Problem Definition: The complex, bespoke shapes that are required to be cut from the Polycarbonate stock sheets for conservatory roofing meant that wastage was high and cutting with saws meant that the dust would contaminate the flutes. The time spent cleaning the product would almost be as long as it would be to cut the material. A means of processing the material quickly, accurately and safely was needed.

Problem Solution: The machine was developed with the following objectives: Reduce wastage, improve cut quality, decrease cuttin and cleaning times. Very quickly, a knife was chosen to cut the sheets rather than a saw. This ensured that the cut was a good quality and eliminated the need for cleaning the product after cutting. This method was bench tested first before being accepted into the design.

The wastage problem was addressed by use of a optimisation and job batching software. The user can enter several jobs into the system at one time, and then the optimisation programme uses all of the jobs to create the cut files. This ensures that the lowest possible wastage can be achieved. The software outputs a CNC file for the machine to read from.

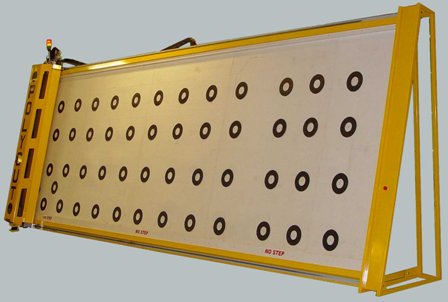

The machine was vertically mounted to provide the minimum amount of factory floor space is needed, thus reducing the costs of ownership.

The Polycut is a CNC Machine designed specifically for cut-to-size Multiwall Polycarbonate Sheet that is commonly used in conservatory roofing, car ports, green houses and other glazing applications.

POLYCUT CASE STUDY

The Double Bed Polycut allows one cut sheet to be removed and the next sheet to be loaded whilst the machine is still cutting on the opposite bed. This "pendulum" system enabled the customer to increase cutting capacity from 160 to 300 sheets per shift.

Variants:

The Polycut has been

developed for different

customer requirements.

The Double Bed machine increased capacity for cutting single sheets at a time.

However, some other customers wanted to increase the cutting capacity by cutting more than one sheet at a time into the same sized panels. The obvious route was to develop the Multicut machine that allows the user to cut up to 5 sheets at once.

Other variables in the machine include differing bed sizes and replacement of the cutting knife with a scorer or marker to draw templates or mark out cutting lines on a wide range of sheet materials.

Engineering Efficiency

Copyright © 2009 Alta Lifts Limited All Rights reserved · E-Mail: sales@polycut-uk.com